bring your HOME to life with unique surfaces:

The finish materials you use for the surfaces around your home can become some of the most important focal points in your home. Using a carefully selected wood for interior floors, cabinets, and other surfaces can add a unique tactile effect that exudes beauty and luxury. Take advantage of our carefully curated wood options to bring your home to a new standard.

USES:

Maple wood can be used for interior flooring, cabinets, interior paneling, veneer, and millwork.

Color Range

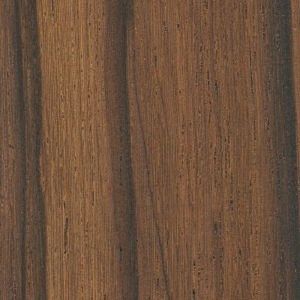

Maple is one of only a few heartwoods where the sapwood lumber is used more than the heartwood. Maple sapwood colors range from nearly white to an off-white cream color, sometimes with a yellowish, reddish, or golden hue. The heartwood of Maple is a medium reddish brown.

Maple wood is rarely stained. It will exhibit moderate color variation from board to board though, so hand selecting the lumber is important.

Grain & Visual Pattern:

The visual grain pattern in Maple changes based on the log and cut, but it generally has an even, fine texture and a natural luster. Maple is mostly a straight grained wood, but sometimes has a wavy grain. Maple wood can also be found with curly or quilted grain patterns, and anomalies like birdseye and quilted. Curly Maple is best displayed through quartersawing. Birdseye maple, commonly seen in hard maple, has tiny knots in the grain that resemble small bird’s eyes (we have included a photo above). Because the knots are tiny, the birdseye figure is most pronounced on flatsawn pieces of lumber. Quilted Maple is less common in hard maple. It has a blistered appearance, and is named for its resemblance to patchwork patterns seen on fabric quilts (see photo above). Similar to birdseye, the figure on quilted maple is most prominent when the board has been flatsawn. There are widely varying grades of patterned maple, based on the perceived depth of the pattern, as well as the purity of the color. The price of the wood varies accordingly. Hand selecting maple boards is extremely important.

Texture and Finish:

Maple wood has a smooth and even texture, so it’s easy to finish with a light brush or smooth sand.

Staining Maple is not needed. Like most woods, it will darken naturally, but it is chosen for its lighter color. Its color and grain can be displayed with a simple matte or gloss finish. However, due to the many different grain anomalies found with different cuts, choosing the correct Maple boards with the right patterns is very important.

Environmental

Hard Maple is not listed in the CITES Appendices or the IUCN Red List of Threatened Species.

We source our Maple boards from trees cultivated in the United States by environmentally responsible harvesters. When the building industry sources and manufactures building materials with sustainability in mind, we all live in a healthier world.

Workability:

Maple is fairly easy to work with when straight-grained. It works easily with our CNC machines, as well as hand tools, though it is a very dense wood. Maple also has a tendency to burn when being machined with high-speed saws and routers. Maple is a difficult wood to stain, and can sometimes result in a blotchy look–we recommend not staining it. Special additional procedures have to be used if staining it to get an even color.

Decay Resistance:

Maple is rated as non-durable to perishable. It holds up very well over time when manufactured properly and used indoors.

Performance

TEST |

U.S. Measurement |

International measurement |

|---|---|---|

| Janka Hardness: | 1,450 lbf | 6,450 N |

| Average Dried Weight: | 44.0 lb/ft³ | 705 kg/m³ |

| Modulus of Rupture: | 15,800 lbf/in² | 109.0 MPa |

| Elastic Modulus: | 1,830,000 lbf/in² | 12.62 GPa |

| Crushing Strength: | 7,830 lbf/in² | 54.0 MPa |

| Density: | 40-47 lb/ft³ | 620 kg/m³ |

| Shrinkage: | Radial: 4.8%; Tangental: 9.9%; Volumetric: 14.7% |

83%+ Clear:

We start with Select & Better graded lumber that is at least 83% clear on one side.

Kiln dried:

All of our wood is kiln dried and stored in a protected warehouse.

We store our wood as S4S, which stands for “surfaced on 4 sides.” The boards have two flat and parallel faces and two flat and parallel edges. The boards are first surfaced on both faces (S2S) with a planer, and receive a rip on both edges.

BULK Commercial Pricing

Because we have become known for our unique material selection, we do sell wood slabs to third parties. If you are working on a large project and in need of large amounts or slabs, we can offer great pricing for bulk orders. We can also finish the wood for your project. However, our wood is hand selected for superior appearance and performance, so contact us to confirm availability and to receive a quote.