bring your Interior to life with unique surfaces:

The finish materials you use for your interior surfaces can become some of the most important focal points. Using a carefully selected wood for cabinets, interior floors, and other surfaces can add the unique tactile effect that exudes beauty, sophistication, and luxury. Take advantage of our carefully curated wood options to introduce a new standard.

USES:

Hickory is a dynamic wood for high-end cabinets, flooring, wall surfaces, and trim.

Color Range

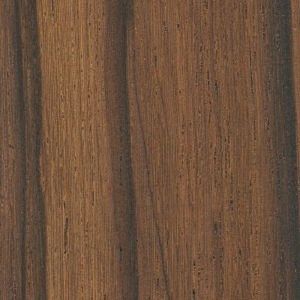

Hickory heartwood is light to medium brown, with lighter or darker rays, and sometimes a reddish tint. The sapwood is much lighter, from white to a pale yellowish brown. Many boards offer a contrasting sapwood and heartwood, creating a more rustic aesthetic. Both colors will darken with age.

Hickory can exhibit strong color variation from board to board. Hand selecting the lumber is important.

Grain & Visual Pattern:

Hickory’s grain variations allow for a wide range of visual patterns. Its grain can be straight and refined, or wavy and even irregular with a rugged appearance. It is close-grained with open, medium-sized pores.

Heavily patterned Hickory boards are best displayed through quartersawing. There are widely varying patterns with Hickory, and different pattern depths, and purity of color.

Rustic Hickory can commonly be found with knots, worm holes and tracks, burls, pin holes, and mineral streaks.

The visual pattern in Hickory changes based on the grain type, the log and the cut, and the price of the Hickory lumber varies accordingly. Figured and quartersawn boards are more expensive. Hand selecting individual Hickory boards for your project is recommended to find your tailored look.

Texture and Finish:

Hickory wood has a smooth and even texture, making it easy to finish with a light brush or smooth sand.

Staining Hickory is not needed but is quite common. Like most woods, it will darken over time with exposure to light.

Its color and grain can be displayed with a simple matte or gloss finish. However, due to the many different grain and pattern anomalies found with different cuts, choosing the right Hickory boards for your project is recommended.

Environmental

Hickory is not listed in the CITES Appendices, or on the IUCN Red List of Threatened Species.

We source our Hickory boards from trees cultivated by environmentally responsible harvesters in the United States. We believe when the building industry sources and manufactures building materials with sustainability in mind, we all live in a healthier world, and we want to do our part.

Workability:

Hickory is difficult to work with because it is so hard and dense. However it is easy to glue, stain and finish — joints and glue-ups will remain intact.

Decay Resistance:

Hickory is rated as non-durable to perishable. However, due to its hardness, density, and strength, it holds up very well over time when manufactured and finished properly.

Performance

TEST |

U.S. Measurement |

International measurement |

|---|---|---|

| Janka Hardness: | 2,140 lbf | 9,520 N |

| Average Dried Weight: | 52 lb/ft³ | 835 kg/m³ |

| Modulus of Rupture: | 20,100 lbf/in² | 138.6 MPa |

| Elastic Modulus: | 2,260,000 lbf/in² | 15.59 GPa |

| Crushing Strength: | 9,190 lbf/in² | 63.4 MPa |

| Density: | 37-58 lb/ft³ | 830 kg/m³ |

| Shrinkage: | Radial: 7.2%; Tangental:11.5%; Volumetric: 17.9% |

83%+ Clear:

We start with Select & Better graded lumber that is at least 83% clear on one side.

Kiln dried:

All of our wood is kiln dried and stored in a protected warehouse.

We store our wood as S4S, which stands for “surfaced on 4 sides.” The boards have two flat and parallel faces and two flat and parallel edges. The boards are first surfaced on both faces (S2S) with a planer, and receive a rip on both edges.

BULK Commercial Pricing

Because we have become known for our unique material selection, we do sell wood slabs to third parties. If you are working on a large project and in need of large amounts or slabs, we can offer great pricing for bulk orders. We can also finish the wood for your project. However, our wood is hand selected for superior appearance and performance, so contact us to confirm availability and to receive a quote.