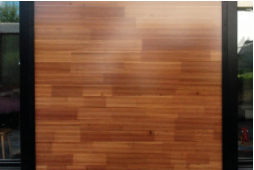

wall panels for every application

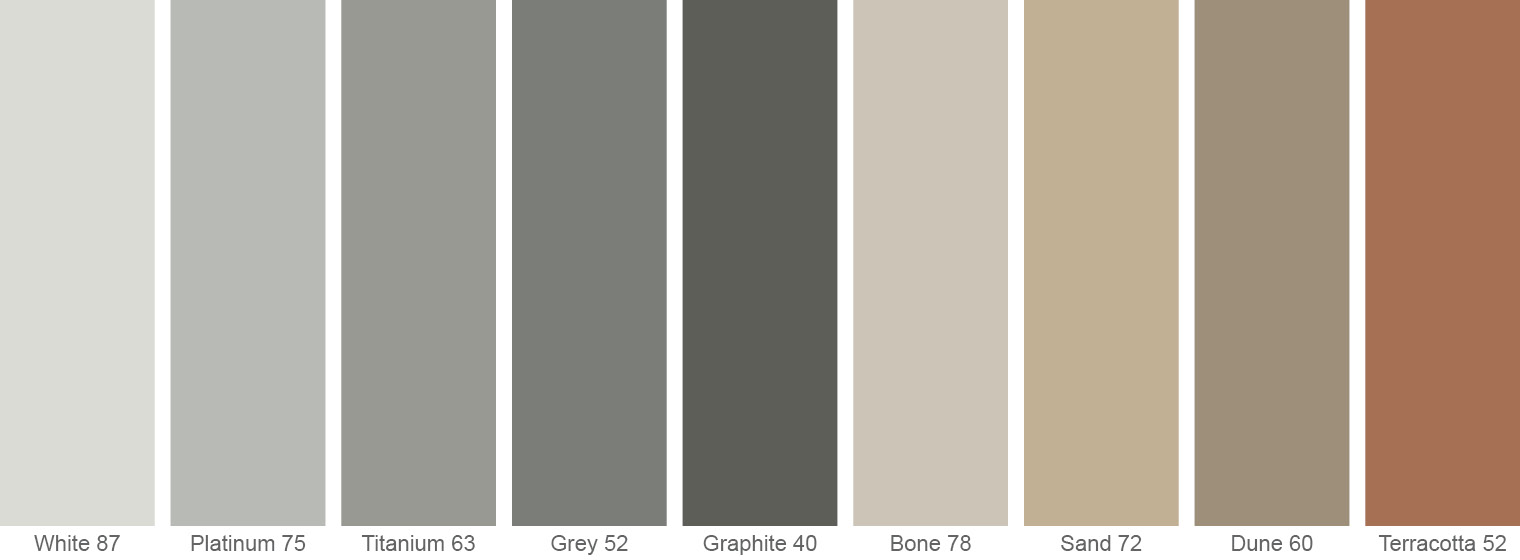

Colors

Below are the standard colors that were developed for the building industry, but custom colors can be made upon request for projects needing excess of 5,000 square feet. Saturated colors are achieved with UV stable pigments that are integrated with the mix, and protected by the dense UHPC matrix.

Because UHPC is a natural, mineral-based product, in generally exhibits subtle color variation between panels. To minimize color variation, we take the following steps:

- Climate and humidity controlled curing chambers

- Tight specification and control of pigments and micro-aggregates

- Precise material dosing to achieve exact mix

- Stringent quality management procedures for incoming raw materials

* Darker colors have greater chance of color variance

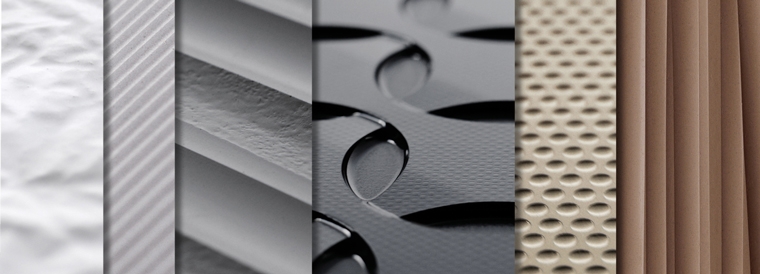

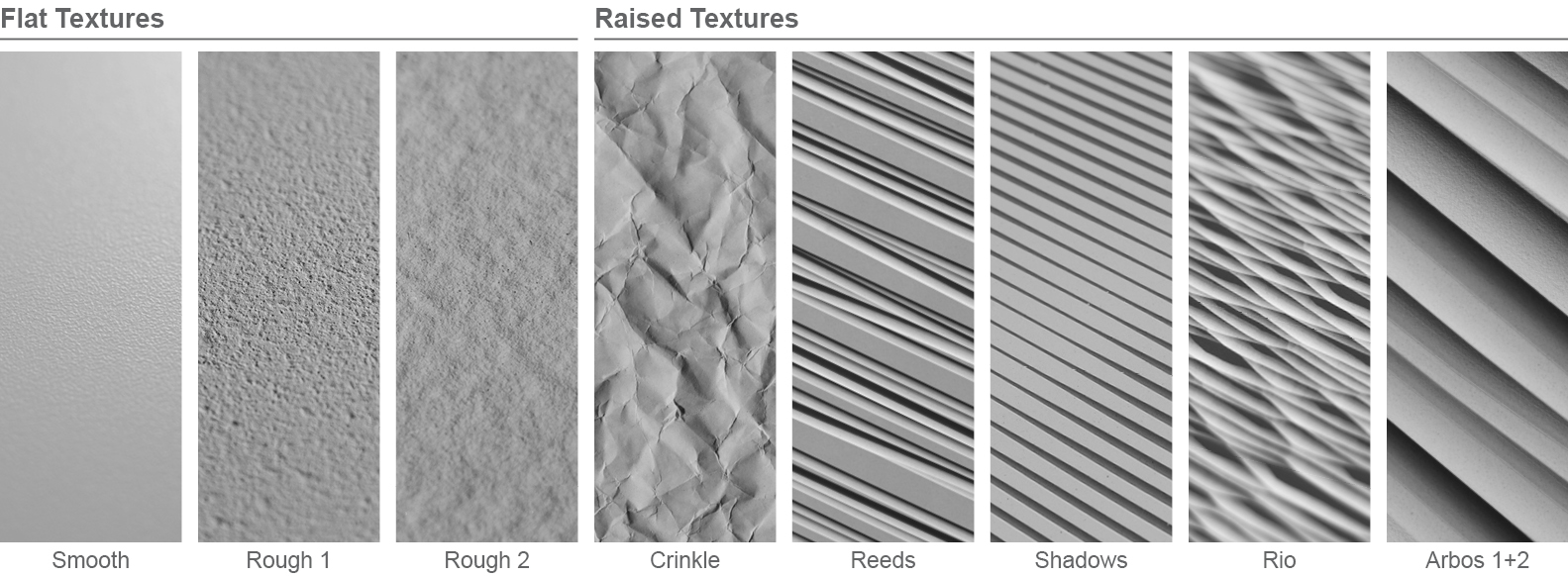

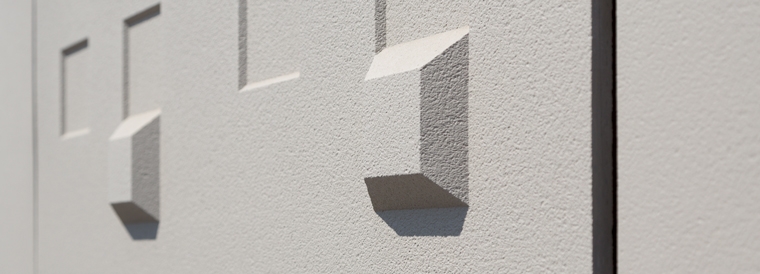

Textures and visual range

Gast Home UHPC panels provide architects and contractors with a broad range of visual options. Because we design and manufacture our molds in-house, we can offer almost any aesthetic desired. Below are just a few examples of textures we can produce.

Mediablasting creates a subtly lighter and more visually varied surface of exposed aggregate. We can also incorporate aggregates of varying color and size into the face of the panels. Custom aggregate finishes can be used for quantities in excess of 10,000 square feet.

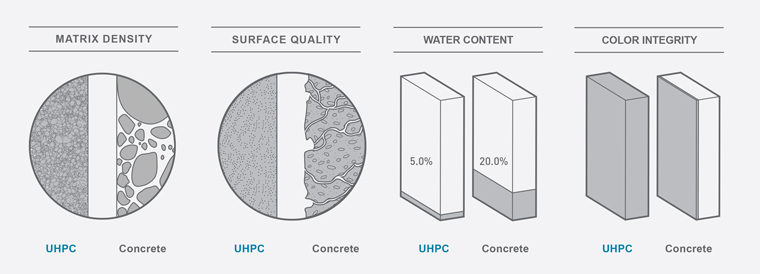

Ultra strength material

UHPC is four times as strong as regular concrete, while providing a broader palette of colors, texture, and geometry. It will not degrade from freeze thaw conditions or from salt. UHPC derives its high performance from a carefully calibrated ratio of engineered ingredients, and a production sequence that packs molecules closer together to form stronger bonds. This higher density provides more compressive and tensile strength, while minimizing the capillary pores that cause degradation in other cement-based products. Other benefits are:

- Freeze/thaw strength

- Anchor pullout strength

- Impact resistance

- Non-combustible; fire-tested for tall buildings

- Low Coefficient of Thermal Expansion

- Non-absorbent and watertight

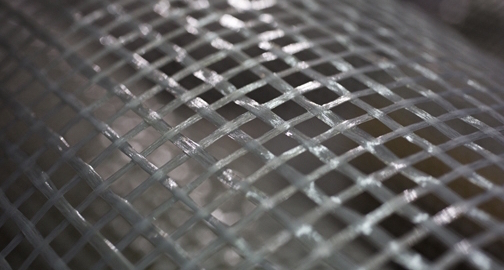

Gast Home UHPC panels are reinforced with Alkali Resistant (AR) Glass Fiber and two layers of AR Glass Fiber mesh. Our panels are cast into molds that create intrinsic patterns and finishes. Special surface effects are created with different molds, aggregates, or sometimes different mediablasting techniques.

weather and weather testing

UHPC gains most of its strength during the first month after being cast, but it will continue to cure for several years. This curing reaction is hydration in the material – water molecules creating bonds with cement – and the panels will weather when exposed to rainwater and other ambient moisture. The subtle color changes will eventually blend together and create the non-homogenous look of a natural material.

Weathering is measured according to ASTM G155. Gast Home uses in-house Xenon-arc weathering chambers for testing. Third party laboratory certified testing of custom colors can be arranged for an additional charge.

In addition to accelerated weather testing, we also conduct extensive outdoor weathering tests including sun, precipitation, and chlorides.

joints and thermal movement

Joint size is determined by designer preference, installation tolerances, and building movement. Thermal movement in negligible and does not affect joint size. The coefficient of linear expansion of a 36″ panel over a 68 degree Fahrenheit temperature swing is 0.016″ (0.4mm).

Certifications

Gast Home UHPC panels are tested according to the methods for ASTM C1185. These products have been certified to meet the standards of ASTM C1186, which is the International Building Code referenced standard for exterior fiber cement panels. All test results exceed the requirements for classification of Type A, Grade IV (highest grade).

environmental impacT

UHPC use can dramatically reduce the environmental impact of cement products by replacing 4′ concrete panels with 5/8″ panels. Less cement is used, reducing CO2 emissions, and weight is reduced for transportation.

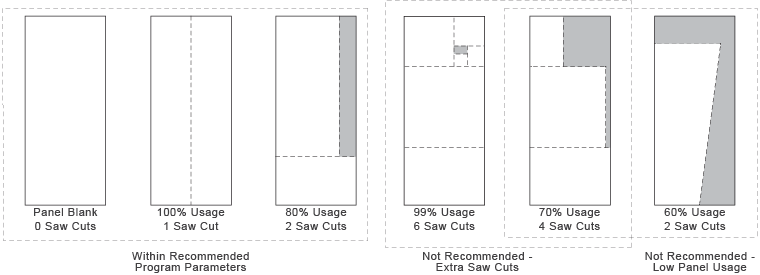

We also maximize our panel usage to reduce waste.

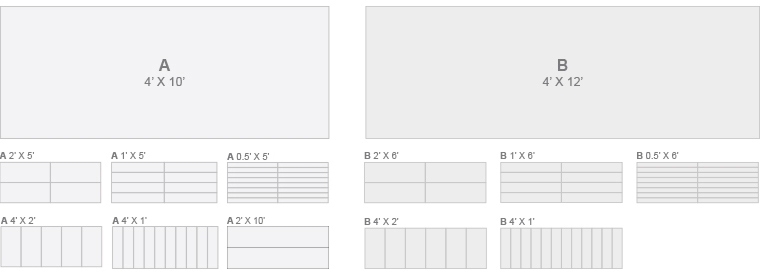

We recommend that all customers utilize 4’x10′ or 4’x12′ modules, where designers can still create a wide variety of layouts to make facades that celebrate the textural quality and materiality of our UHPC panels. Below are also the resulting sizes which can be cut from these large panels.

Custom panels

Gast Home has developed a wide range of custom textures, patterns, perforations, shapes, and profiles. However we are always looking to innovate and drive forward new technologies, systems, and methods in pursuit of the best solutions for the end user at the best price. Please contact us as soon as possible in the design process, so that our team can assist you in optimizing for material performance, manufacturing process, and budget.

The maximum panel size is 144″ x 48″ (3657mm x 1220 mm). All panels will be 5/8″ (15.9mm) in thickness.

Installation of UHPC Panels

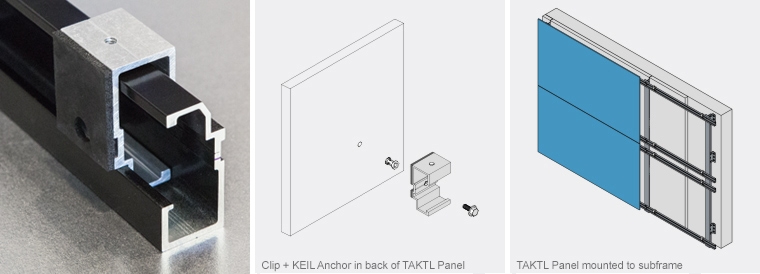

Gast Home UHPC exterior wall panels are primarily used for back ventilated facade wall assemblies (rainscreen), with or without continuous exterior insulation. They are also compatible with a wide range of sub-frame products, and can be used with curtain wall fabrications with horizontal and continuous rail orientation attached to a sub-frame.

Gast Home offers single-source ordering for several mounting hardware components and systems for our UHPC panels. We offer rails, clips, face fasteners, and concealed anchors.

- Rails are available in 12′, 16′ and 20′ lengths

- Panels are factory drilled for KEIL undercut anchors and can be shipped with clips attached

- Clips and rails are made from recycled content

UHPC panels intended for concealed attachment are factory drilled for KEIL undercut anchors exclusively. Our clip extrusion profile is designed specifically so that KEIL undercut anchors mechanically engage the panel without transferring internal stress.

Gast Home UHPC panels are cut to size and the holes drilled for fasteners in our factories. Panels can even be cut to size and drilled on the jobsite. With fewer anchor points required per panel, installation can be efficient and cost effective.

exposed fastening options

UHPC panels can be attached to the substructure frame with screws or rivets that can be seen in the panels. Our options include stainless steel or color matched heads for surface or flush-mount applications.

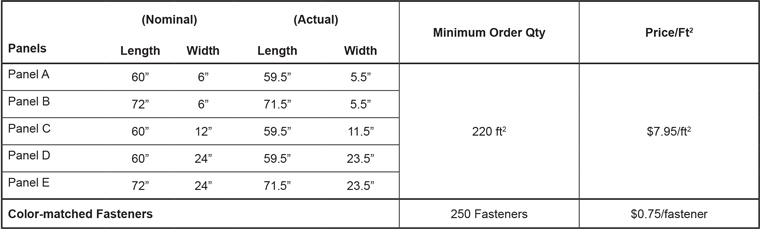

Pricing

design and technical support

Gast Home designers and project managers are typically involved in projects from start thru manufacturing, delivery, and even installation. We provide expertise at each step in the process, and are always here to help with what you need. Please contact our Technical Support Team with any requirements.

cost comparison, Quality, and timing

By controlling the entire process, and with vertical integration, Gast Home is able to achieve efficiencies, eliminate distribution markups, and bring projects in at a lower cost and in less time.